How does winery wastewater treatment work?

Wineries are invaluable for producing wine in large quantities, but the crushing process behind this can lead to a lot of wastewater – up to 32 litres of it per litre of wine! This is partly due to natural spillages but is also due to the wineries using water to sanitise and clean the press or even the grapes themselves. With that in mind, if you work in a winery, you should know exactly how to treat wastewater that builds up with each use of the press. Here is a guide to the treatment process.

1. Reducing the wastewater content

Less wastewater means less treatment, making it a cleaner procedure for all. For this reason, you should implement various techniques to minimise waste generation during the winemaking process. This might be as simple as being more careful to prevent unnecessary spillages or cleaning in more efficient ways; dry cleaning processes can go a long way towards reducing water use, as can high-pressure cleaning if this is not possible.

2. Analysing the wastewater effluents

The next step to treating winery wastewater is for a treatment company to inspect its components. Despite the name, the wastewater won’t be 100% water – it will also contain plenty of effluents that have ethanol, sugars, and even solid concentrations. The composition can vary depending on the season and the particulars of the winemaking operation; nonetheless, wastewater won’t be readily disposable without prior treatment.

3. Separating the solids

The treatment company will begin the treatment process properly by removing the solids within, if applicable. These solids could be big enough to affect the rest of the process if you do not deal with them first – you can remove up to 40% of the organic matter in the wastewater through this step alone, and decantation will take care of them afterwards. In this step, the company also changes the pH of the wastewater to release the neutral effluent into the sewer system when appropriate.

The treatment company will begin the treatment process properly by removing the solids within, if applicable. These solids could be big enough to affect the rest of the process if you do not deal with them first – you can remove up to 40% of the organic matter in the wastewater through this step alone, and decantation will take care of them afterwards. In this step, the company also changes the pH of the wastewater to release the neutral effluent into the sewer system when appropriate.

4. Secondary treatment

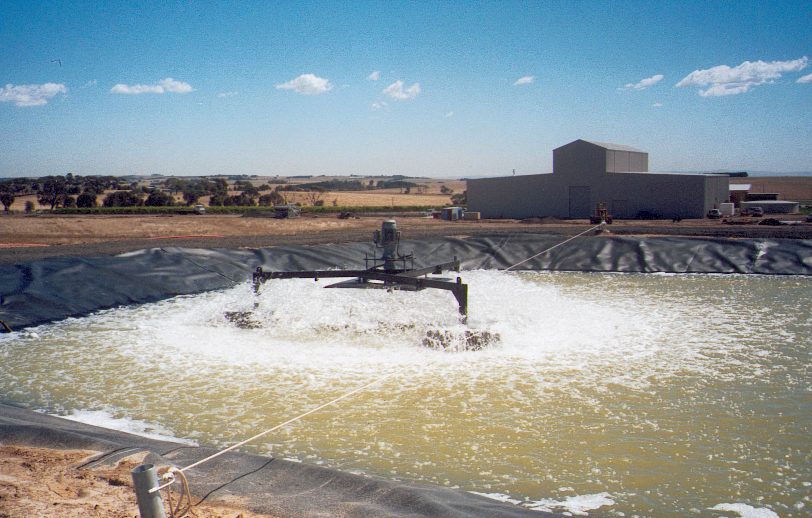

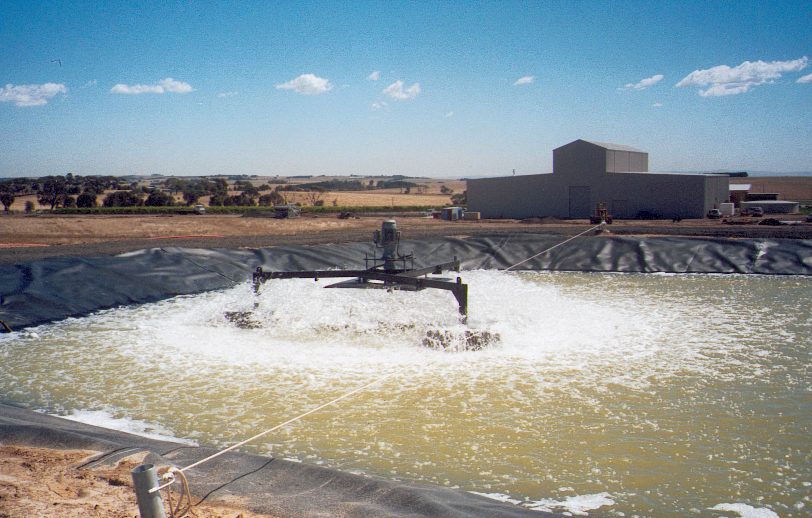

Afterwards, the wastewater still needs additional treatment to remove all of the dissolved organic matter; the method for this can vary based upon a litany of factors. Regardless, you’ll need a treatment system, one which works for the minutiae of the wine operation – the aerators, for example, must be able to handle variations in pH, flow, temperature, and more. This particular component will provide oxygen to the bacteria that perform the aerobic biodegradation of the different substances, making it invaluable for the treatment process.

You cannot underestimate the importance of winery wastewater treatment; with the right approach, you can recycle it for better use or reduce your water use in the first place. By Jas specialises in sewage and wastewater treatment; visit us at www.byjas.com.au or call us on (03) 5979 1096.

We have been working in the industry for 35 years and are proudly family-owned. We use this experience and dedication to provide our service across Australia, including regional town centres, remote regional areas, and main capital cities. Contact us today for a free quote on our services.

SHARE:

What you can read next

Waste water treatment for Wineries

Wineries across Australia are producing record ...

Specialising in the Winery Industry

We cater to the winery industry in order to red...

Irrigation efficiency for Wineries

As we know wineries produce wastewater from the...

What is Involved in the Process of Winery Wastewater Treatment?

Winery wastewater is generated from the winery’s...

Want to remove waste water efficiently

Are you looking for a cheaper and more environmen...

Why Choosing a Wastewater Equipment Manufacturer Provides a Better Option?

Why Choosing a Wastewater Equipment Manufact...

Why Are Bacteria Used in Sewage Treatment?

Wastewater treatment is society’s way of giving...